Your AI partner for the new era

Your AI partner for the new era

Your AI partner for the new era

Your AI partner for the new era

Last Modified: January 27th, 2026

Margins are thin. Every minute lost in setup, a bad offset that ruins a part, or an unexpected stoppage eats your profit—literally. You feel it every shift. It’s exhausting.

Here’s the bright side: AI for CNC shops can make the machines you already own faster, steadier, and more predictable—without hauling in new capital. Think quicker setups, smarter feeds and speeds, real‑time quality alerts, and fewer do‑overs. Less scrap, fewer stoppages, more parts out the door.

This article skips the hype. You’ll get practical, low‑risk ways to apply AI on the shop floor and how to prove ROI fast—often in weeks, not months. No rip‑and‑replace. Just targeted wins that stack up to cut setup time, reduce scrap, and boost throughput. Ready to see where it moves the needle? Let’s dive in.

AI creates leverage where your profit leaks: faster setup and programming, fewer defects and rework, and steadier machine availability. Nail those three and the rest follows.

Setup minutes per job. Measure from the last good part of the previous job to the first good part of the next—fixtures on, tools loaded, offsets set, prove‑out done. Baseline it for your top 10 repeat jobs. The goal: cut changeover time and reduce prove‑out edits. Even a 20–30% drop gives you real capacity without buying a single machine.

First‑pass yield (FPY) and scrap rate. FPY = good parts with no rework ÷ total produced. Pair that with scrap rate by job, material, and machine. You’ll quickly spot where offsets drift, tool wear bites, or a feature is mis‑programmed. AI helps standardize best settings, spot anomalies early, and prevent the second scrap part that always follows the first.

OEE and throughput. Keep it simple: Availability (spindle on vs planned), Performance (actual cycle vs standard), Quality (FPY). Better OEE means more parts per shift and fewer surprises. Track parts per hour at the constraint machine; that’s your throughput heartbeat. If it’s rising, you’re winning.

To pick a pilot, choose a high‑mix runner with long changeovers, a chronic scrap offender, or a bottleneck spindle. Set clear targets—e.g., −25% setup minutes, +5 points FPY, +10% OEE—and measure weekly. ROI is straightforward: minutes saved × burdened rate + scrap avoided + extra parts shipped. You dont need fancy dashboards to start—just disciplined tracking.

Want the fastest dent? Start with setup.

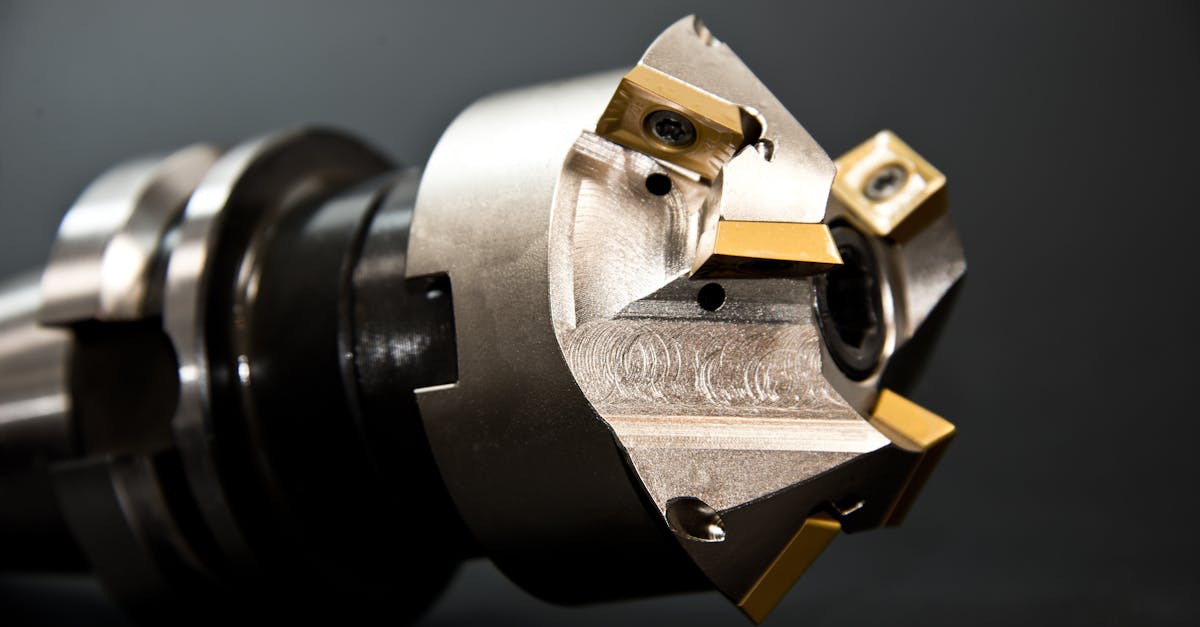

Programming and setup steal more hours than anyone admits. AI‑assisted CAM flips that. It auto‑recognizes features, suggests proven tooling and feeds/speeds, and generates optimized toolpaths—so you spend less time clicking and more time cutting chips.

Import your model and let feature recognition tag holes, pockets, threads, and chamfers. The system maps those to your tool library and best‑practice templates, then proposes ops in the right order. Fewer manual edits. Fewer dry runs.

Toolpath optimization trims air‑cuts and unnecessary rapids, and collision‑aware simulation catches gouges before they become scrap. If you want proof, these case studies on AI‑assisted programming and toolpath optimization show real shops cutting programming time and lifting uptime.

Prefer to “tell” the plan? Natural‑language inputs let you describe the job—“face, rough, finish 6061 plate, ±0.02, 3/8 end mill”—and get a starter ops list with feeds/speeds and workholding hints. You’re not replacing your CAM brain, just speeding it up.

Then lock consistency with digital setup sheets auto‑generated from CAM: tool list and lengths, fixture photos, probe points, torque specs, offsets, and a short prove‑out checklist. Version‑controlled and QR‑coded at the machine, so any operator can hit the same result, first time.

The payoff? Faster changeovers, fewer prove‑out tweaks, and less reliance on tribal knowledge. Don’t overthink it—standardize the wins, and the first good part shows up sooner, shift after shift.

Most scrap starts the same way: a tool dulls, chatter creeps in, finish falls off, dimensions drift. By the time you notice, you’ve made a few bad parts. AI changes the timeline. Models read signals you already have—spindle load, vibration, even acoustic signatures—to estimate tool wear and remaining life, then nudge the process before defects appear.

How it works: pick your constraint ops and common tools. Log spindle load and vibration during normal cuts. A lightweight model learns the signature of a “healthy” cut for each tool/material combo. When patterns shift, it predicts remaining tool life and can trigger a pause, suggest a tool change, or auto‑tune feeds and speeds to protect surface finish. No magic—just smarter guardrails built into your routine.

On finish‑critical parts, surface quality prediction adds another layer. Models forecast Ra/Rz from inputs like tool geometry, SFM, chip load, depth of cut, and wear state, then recommend stable windows that avoid chatter and dimensional drift. For a deeper dive, this scholarly review on tool wear, parameter optimization, and surface quality prediction in CNC outlines what’s proven and why it works.

The impact? Fewer re‑cuts, less material waste, higher FPY. Quick start: pick one chronic scrap offender, collect a week of signals, fit a simple wear classifier, and tie it to an alarm or feed override. You’ll see steadier parts—and you wont be guessing mid‑run anymore.

Catching defects at final inspection is too late. AI vision for CNC and in‑process monitoring let you see problems as they form—in the cut, between ops, before the next part is wasted. Think burrs on an edge, a faint tool mark, a pocket drifting a few thou. Flag it, fix it, keep the run clean.

Set up an enclosure camera with controlled lighting, or a robot‑mounted lens for flexible angles. A model learns the “good” signature of your part and does visual anomaly detection and feature checks. It can highlight edges that didn’t break, roughness that signals chatter, or a mis‑located hole. Tie this to quick probe cycles (or a laser mic) to confirm dimensions without sending parts to QC.

Make it actionable. Define checkpoints: after rough, before finish, post‑deburr. If the system sees an anomaly, it can pause the cycle, prompt a feed/offset adjustment, or call a tool change. Every event logs an image, machine state, and operator note—handy for root cause and training.

Why trust it? Real shops are already reducing rework with real‑time detection of deviations that cuts defects and rework. You dont need a data center: an industrial PC at the machine runs inference just fine.

Result: higher first‑pass yield, fewer firefights, and a calmer schedule. And those vision and sensor streams? They also reveal early wear and machine drift—the perfect inputs for smarter maintenance and planning.

Unplanned stoppages kill throughput. Predictive maintenance uses your machine and sensor data to catch issues early—so you plan service during natural lulls (lunch, shift change, tool preset) instead of fighting breakdowns mid‑run. The result: steadier OEE and more spindle‑on minutes without adding headcount.

Watch early signatures: rising spindle load at the same program line, axis‑current spikes, repeat alarms, thermal drift, or abnormal vibration. Lightweight models learn your normal and estimate remaining useful life for spindles, ball screws, and tools. When risk climbs, the system nudges you to schedule a swap, stage a spare, or temporarily slow a cut to finish the lot. Industry evidence shows predictive maintenance and AI‑driven production scheduling cut downtime and improve flow—exactly what a high‑mix CNC shop needs.

Then keep the flow with smarter scheduling. AI sequences jobs to reduce changeovers and protect the constraint: group by tool/fixture families, route to available machines, and balance due dates with setup penalties. Practical rules—shortest processing time with setup cost, bottleneck‑first dispatch, and auto re‑sequencing when a machine goes down—keep the right parts under the spindle. It also squeezes gaps with quick‑turn ops, so small jobs dont clog the board.

Quick start: pull simple signals (status, load, alarms), flag the top three failure patterns, and pilot a schedule that groups setup families while maximizing runtime on the bottleneck spindle. Even on older controls, simple signals are enough to begin. You’ll see fewer surprises and 5–10% more productive hours per shift within weeks—youre finally running the plan, not the fires.

You dont need new iron. Most legacy CNC machines can be connected with low‑cost gateways and a few smart taps. MTConnect or OPC UA adapters expose data from older controls; simple discrete I/O taps handle cycle start/stop, alarm, load, and part‑count signals. It’s cheap, fast, and reversible—perfect for proving value before you scale.

Start with five signals that pay back quickly: spindle load, axis currents, alarm codes, part counts, and probe results. Stream them to a small industrial PC or secure cloud. With that, you’ll see live cycle status, changeover duration, and where time vanishes between parts. Think of it as turning the lights on across every machine.

What changes? Immediate visibility. Rising spindle load flags a dull tool before scrap hits. Alarm Pareto reveals real blockers, not guesses. Probe drift catches offsets early. These are the building blocks for predictive maintenance and steadier throughput—no rip‑and‑replace required.

If you’re skeptical, this white paper details compatibility with older machines and case studies where real‑time analytics improve throughput. It’s practical, and it works on shops like yours.

Implementation is straightforward: drop in a gateway per machine, map tags to standard names, validate each signal with a short test cut, and publish to a simple dashboard. Most machines can be wired in half a day. From there, AI for CNC shops can sit on top—tool wear alerts, anomaly detection, smarter scheduling—driving measurable gains fast.

Keep it tight, prove impact fast, then expand. Here’s a simple 90‑day plan you can run without pausing production.

Weeks 1–2: Select and baseline. Pick one target cell or part family with pain (long changeovers, frequent scrap, or a bottleneck spindle). Baseline setup minutes per job, FPY/scrap, and uptime. Map the signals you can access today (spindle load, part count, alarms, probe hits), note data gaps, and assign an owner. Document the current setup steps and tooling so you can compare apples to apples later.

Weeks 3–6: Connect and choose one use case. Wire the machines you selected, start streaming basic signals to a lightweight dashboard, and validate data with a short test cut. Stand up simple views: setup duration, cycle status, and alarm Pareto. Choose one use case—tool wear alerts or AI‑assisted CAM—and define success criteria (e.g., −20% setup on Job A, −30% scrap on Op 20, +8% parts/shift). Build digital setup sheets for your top three repeat jobs.

Weeks 7–10: Run the pilot and tune. Train operators in a quick huddle, run the workflow on live jobs, and record every exception (what happened, action taken, result). Adjust thresholds, feeds/speeds windows, or setup steps weekly. Lock in what works; kill what adds noise. Keep changes small so throughput isnt disrupted.

Weeks 11–12: Prove ROI and standardize. Calculate ROI: minutes saved × burdened rate + scrap avoided + extra parts shipped. Codify standard work (updated setup sheets, alert playbook, maintenance triggers) and decide the next cell to roll out—preferably where the same templates apply. That’s how wins compound, without drama.

Start small. Prove ROI. Then scale. You don’t need new iron or a rip‑and‑replace project to see results. Well‑scoped AI pilots—on the machines you already own—can cut setup time, reduce scrap, and unlock more productive hours fast. Keep it practical, visible, and tied to the parts that actually pay the bills.

Pick one high‑impact use case, define clear metrics, and baseline. Run it for a few weeks, tune the thresholds, and standardize what works. When it sticks, roll the same playbook to the next cell. That’s how AI for CNC shops goes from “interesting” to everyday: CAM templates that shorten changeovers, digital setup sheets that preserve tribal knowledge, tool‑wear alerts that prevent the second scrapped part, and predictive maintenance that keeps the spindle on.

The best part? It’s low risk and measurable. Minutes saved × burdened rate, scrap avoided, extra parts shipped—Youll see the numbers move. Even a modest 20% setup reduction or a 5‑point FPY lift compounds across weeks. And the calmer schedule you get back is worth more than it looks on paper, trust me.

If you want a partner to de‑risk the pilot, wire up legacy machines, and integrate with your existing CAM/ERP, we can help. 1808lab is an AI consulting company for SMBs that implements these use cases end‑to‑end. Reach out to our team to plan a practical pilot and scale the wins across your shop.